Basic Info.

Model NO.

FH

Horsepower

351-450hp

Engine Capacity

6-8L

Tire Certification

ECE, GCC, ISO, DOT

Tire Design

Tubeless

Condition

New

Color

Yellow/Black

Customized

Workable

OEM/ODM

Workable

Label

Customized

Transport Package

Cartons/Seaworthy

Specification

10T--60T

Trademark

FINER

Origin

China

HS Code

84289090

Production Capacity

90000000000 Sets/Year

Product Description

Air Casters: Revolutionizing Material Handling and Transportation

Air Casters Introduction:

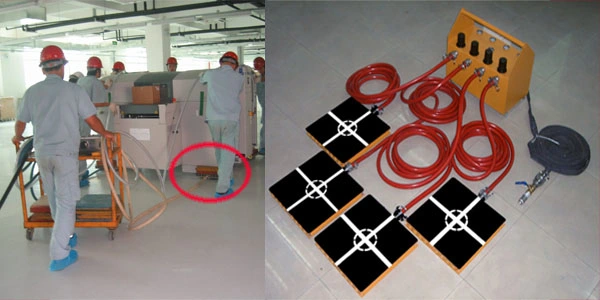

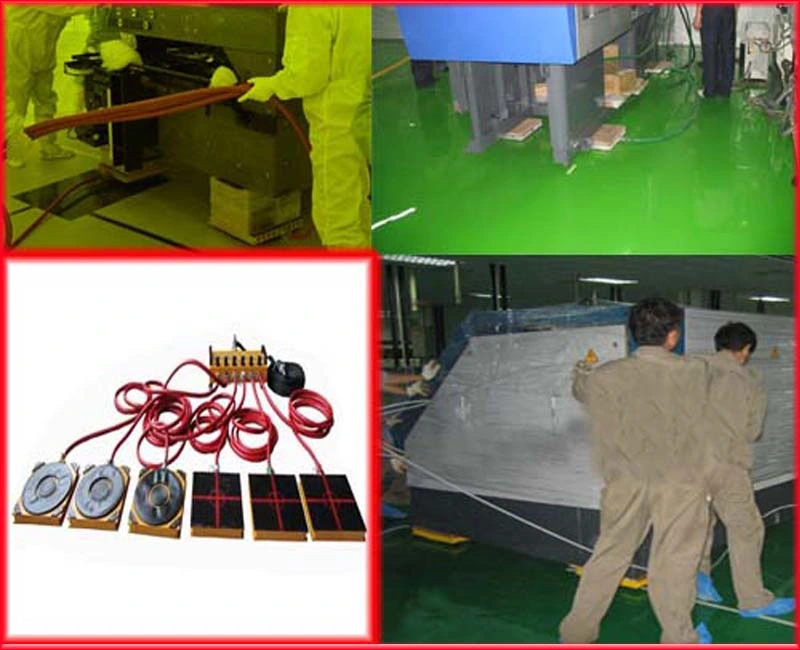

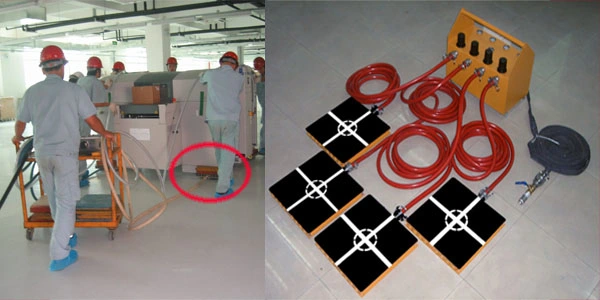

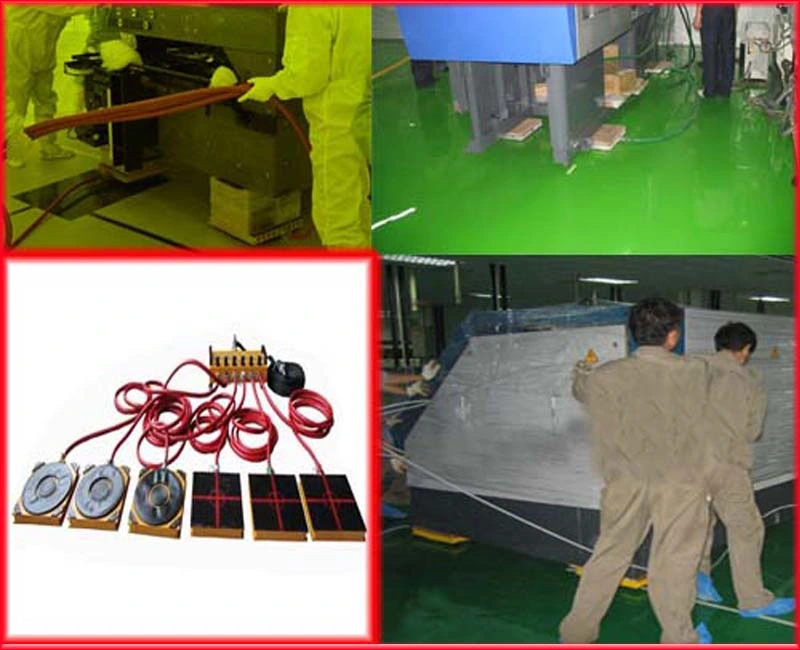

In material handling and transportation works, air casters is simplify processes, increase efficiency, and reduce physical strain.

What are Air Casters?

Air casters, also known as air skates, are a type of load-moving equipment that utilizes compressed air to lift and float heavy loads, eliminating the need for traditional wheels or rollers. These devices consist of a flexible air film, usually made of reinforced rubber or polyurethane, which creates a cushion of air between the load and the ground, enabling easy movement in any direction.

Working Principle:

The working principle of air casters is based on the concept of air flotation. When compressed air is introduced into the air casters, it escapes through tiny holes in the air film, creating a thin layer of air between the load and the ground. This air cushion significantly reduces friction, allowing the load to glide effortlessly over the surface. The amount of air pressure determines the lifting capacity and the ease of movement.

How to Operate Air Casters:

Operating air casters is relatively simple and straightforward. The process typically involves the following steps:

1. Preparation: Ensure the load is properly balanced and secure. Clean the floor surface to remove any debris or obstacles that may hinder movement.

2. Positioning: Place the air casters evenly beneath the load, ensuring equal distribution of weight. Connect the air supply hose to the casters.

3. Inflation: Gradually introduce compressed air into the air casters, monitoring the pressure to achieve the desired lifting capacity. Avoid overinflating, as it may cause instability.

4. Movement: Once the air casters are inflated, the load will start to float. Gently push or pull the load in the desired direction, using manual force or other machinery. Take caution to avoid sudden movements or jerks.

Air Casters Working Conditions:

Finer brand Air casters are designed to operate effectively in various working conditions, including:

1. Load Weight: Air casters are suitable for handling heavy loads ranging from a few hundred kilograms to several tons, depending on the specific model and configuration.

2. Floor Surface: Air casters work optimally on smooth, clean, and level surfaces. However, they can also function on rough or uneven floors, although the load capacity may be slightly reduced.

3. Environmental Factors: Air casters are resistant to most environmental conditions, such as temperature variations, humidity, and dust. However, extreme temperatures or corrosive environments may require additional protective measures.

Advantages of Air Casters:

Air casters offer numerous advantages over traditional material handling methods, including:

1. Weight Distribution: Air casters distribute the load weight evenly, minimizing the risk of damage to the floor or the load itself.

2. Versatility: Air casters allow multidirectional movement, enabling operators to maneuver loads effortlessly in tight spaces or confined areas.

3. Floor Protection: The air cushion created by air casters eliminates the need for wheels or rollers, significantly reducing the risk of floor damage, such as scratches or marks.

4. Ergonomics: Air casters reduce physical strain and eliminate the need for excessive manual labor, promoting a safer and more efficient working environment.

5. Cost-Effectiveness: By reducing the need for additional equipment, such as cranes or forklifts, air casters offer a cost-effective solution for material handling and transportation.

Finer brand Air casters have revolutionized the way heavy loads are moved and transported, providing a versatile, efficient, and cost-effective solution. By utilizing the power of compressed air, these innovative devices significantly reduce physical strain, increase productivity, and enhance workplace safety. With their ability to glide effortlessly in any direction, air casters have become an indispensable tool in various industries, ensuring smooth and seamless material handling operations.

Shandong Finer Lifting Tools Co., LTD produced and exported Finer brand air castors since 1998, exporting to more than 70 countries and areas. With CE/SGS certificates. Finer Brand Air skates / air casters with a long lifespan can work for more than eight years with no quality problems.

Air skate also named air skids,air caster,air skate load module systems,air trailer,air bearing kit,

air dolly and so on another names.

Air skate is easily to operate and labor-saving,Air skate will protecting your floor from any hurt.

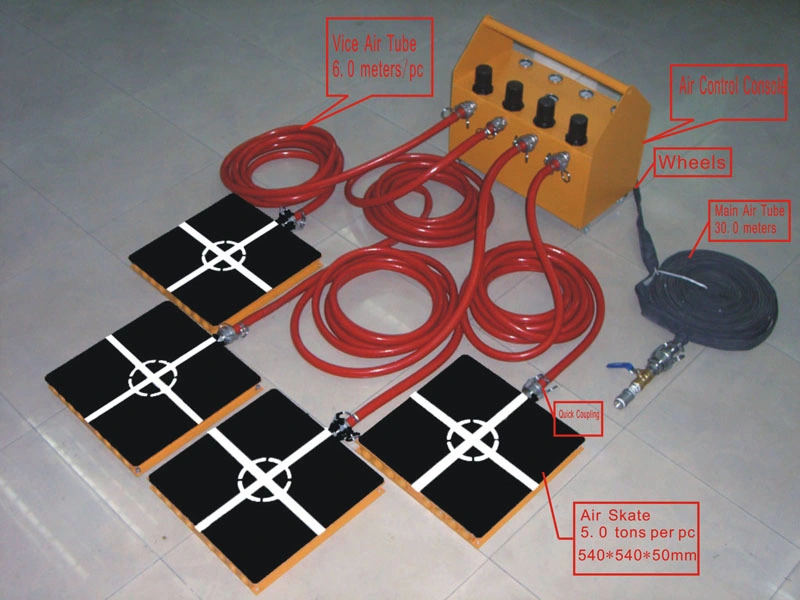

10 tons Air bearing kit have 4 load modules can put anywhere you want as per the central of gravity of equipment

which need moving.

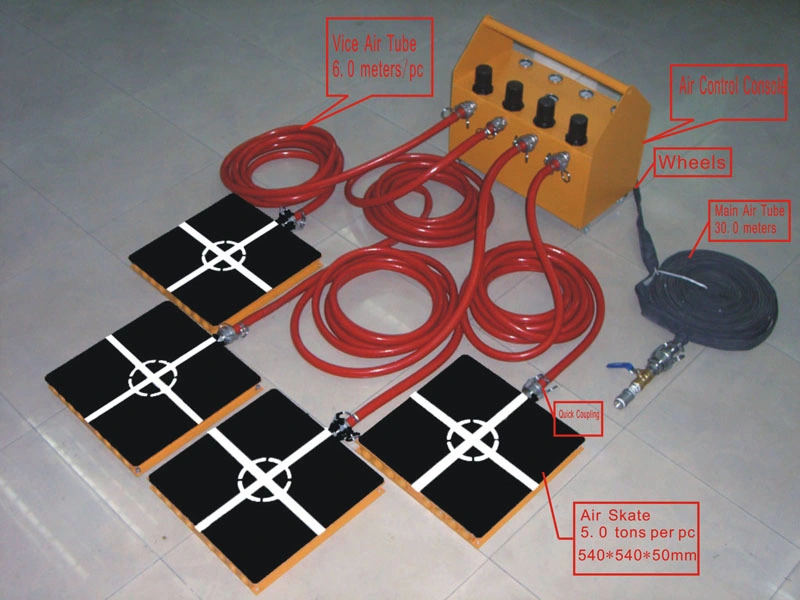

Air bearing kit structure:

one pcs main trachea length is 30 meters,

one air conditioner which have wheels under it is easy to move.

Four pcs vice-trachea,every one length is 6 meters connect four modules.

Four air load modules,every module capacity is 2.5 tons. Size is 380mm*380mm*50mm.

One set 10 tons air skate net weight is 100kg.

FAQ for Quality

Q: How about your quality?

Our quality is durable for more than ten years without any problems. From the year of 1998, we export air bearing casters to the global market with high evaluation.

Q: How about your quality control system?

Before every set of air-bearing casters leaves our factory, we will test every part of the goods, which can be tested by a third party or clients directly.

Q: If the air bearing casters can't work, can you solve it for us?

Yes, Sure. Our quality guaranteed for one year, within one year from you get these goods if there are quality problems, will renew or refund.

Q: Do you accept third part or clients test before the goods leaves your factory?

Yes, Both third part or clients test are workable.

Air Casters Introduction:

In material handling and transportation works, air casters is simplify processes, increase efficiency, and reduce physical strain.

| MODEL | Details | MM*MM*MM |

| 10T FA-10 | Module:2.5t*4PCS Air control console:1set Main air tube:30M*1 Vice air tube:6M*4pcs | 380*380*50mm Pressure:0.4mpa(4kg/cm²) Main air source:3.0m³/MIN Pressure:7kg/cm² |

| 16T FA-16 | Module:4.0t*4 pcs Air control console:1sets Main air tube:30M*1 Vice air tube:6M*4pcs | 485*485*50mm Pressure:0.4mpa(4kg/cm²) Main air source:3.5m³/MIN Pressure:7kg/cm² |

| 20T FA-20 | Module:5.0t*4 pcs Air control console:1sets Main air tube:30M*1 Vice air tube:6M*4pcs | 540*540*50mm Pressure:0.4mpa(4kg/cm²) Main air source:4.0m³/MIN Pressure:7kg/cm² |

| 32T FA-32 | Module:8.0t*4 pcs Air control console:1sets Main air tube:30M*1 Vice air tube:6M*4pcs | 686*686*50mm Pressure:0.4mpa(4kg/cm²) Main air source:5.5m³/MIN Pressure:7kg/cm² |

| 48T FA-48 | Module:8t*6pcs Air control console:1 set Main air tube:30M*1 Vice air tube:6M*6pcs | 686*686*50mm Pressure:0.4mpa(4kg/cm²)Main air source:10.0m³/MIN Pressure:7kg/cm² |

| 60T FA-60 | Module:10t*6 Air control console:1 set Main air tube:30M*1 Vice air tube:6M*6pcs | 686*686*50mm Pressure:0.4mpa(4kg/cm²)Main air source:12.0m³/MIN Pressure:7kg/cm² |

What are Air Casters?

Air casters, also known as air skates, are a type of load-moving equipment that utilizes compressed air to lift and float heavy loads, eliminating the need for traditional wheels or rollers. These devices consist of a flexible air film, usually made of reinforced rubber or polyurethane, which creates a cushion of air between the load and the ground, enabling easy movement in any direction.

Working Principle:

The working principle of air casters is based on the concept of air flotation. When compressed air is introduced into the air casters, it escapes through tiny holes in the air film, creating a thin layer of air between the load and the ground. This air cushion significantly reduces friction, allowing the load to glide effortlessly over the surface. The amount of air pressure determines the lifting capacity and the ease of movement.

How to Operate Air Casters:

Operating air casters is relatively simple and straightforward. The process typically involves the following steps:

1. Preparation: Ensure the load is properly balanced and secure. Clean the floor surface to remove any debris or obstacles that may hinder movement.

2. Positioning: Place the air casters evenly beneath the load, ensuring equal distribution of weight. Connect the air supply hose to the casters.

3. Inflation: Gradually introduce compressed air into the air casters, monitoring the pressure to achieve the desired lifting capacity. Avoid overinflating, as it may cause instability.

4. Movement: Once the air casters are inflated, the load will start to float. Gently push or pull the load in the desired direction, using manual force or other machinery. Take caution to avoid sudden movements or jerks.

Air Casters Working Conditions:

Finer brand Air casters are designed to operate effectively in various working conditions, including:

1. Load Weight: Air casters are suitable for handling heavy loads ranging from a few hundred kilograms to several tons, depending on the specific model and configuration.

2. Floor Surface: Air casters work optimally on smooth, clean, and level surfaces. However, they can also function on rough or uneven floors, although the load capacity may be slightly reduced.

3. Environmental Factors: Air casters are resistant to most environmental conditions, such as temperature variations, humidity, and dust. However, extreme temperatures or corrosive environments may require additional protective measures.

Advantages of Air Casters:

Air casters offer numerous advantages over traditional material handling methods, including:

1. Weight Distribution: Air casters distribute the load weight evenly, minimizing the risk of damage to the floor or the load itself.

2. Versatility: Air casters allow multidirectional movement, enabling operators to maneuver loads effortlessly in tight spaces or confined areas.

3. Floor Protection: The air cushion created by air casters eliminates the need for wheels or rollers, significantly reducing the risk of floor damage, such as scratches or marks.

4. Ergonomics: Air casters reduce physical strain and eliminate the need for excessive manual labor, promoting a safer and more efficient working environment.

5. Cost-Effectiveness: By reducing the need for additional equipment, such as cranes or forklifts, air casters offer a cost-effective solution for material handling and transportation.

Finer brand Air casters have revolutionized the way heavy loads are moved and transported, providing a versatile, efficient, and cost-effective solution. By utilizing the power of compressed air, these innovative devices significantly reduce physical strain, increase productivity, and enhance workplace safety. With their ability to glide effortlessly in any direction, air casters have become an indispensable tool in various industries, ensuring smooth and seamless material handling operations.

Shandong Finer Lifting Tools Co., LTD produced and exported Finer brand air castors since 1998, exporting to more than 70 countries and areas. With CE/SGS certificates. Finer Brand Air skates / air casters with a long lifespan can work for more than eight years with no quality problems.

Air skate also named air skids,air caster,air skate load module systems,air trailer,air bearing kit,

air dolly and so on another names.

Air skate is easily to operate and labor-saving,Air skate will protecting your floor from any hurt.

10 tons Air bearing kit have 4 load modules can put anywhere you want as per the central of gravity of equipment

which need moving.

Air bearing kit structure:

one pcs main trachea length is 30 meters,

one air conditioner which have wheels under it is easy to move.

Four pcs vice-trachea,every one length is 6 meters connect four modules.

Four air load modules,every module capacity is 2.5 tons. Size is 380mm*380mm*50mm.

One set 10 tons air skate net weight is 100kg.

FAQ for Quality

Q: How about your quality?

Our quality is durable for more than ten years without any problems. From the year of 1998, we export air bearing casters to the global market with high evaluation.

Q: How about your quality control system?

Before every set of air-bearing casters leaves our factory, we will test every part of the goods, which can be tested by a third party or clients directly.

Q: If the air bearing casters can't work, can you solve it for us?

Yes, Sure. Our quality guaranteed for one year, within one year from you get these goods if there are quality problems, will renew or refund.

Q: Do you accept third part or clients test before the goods leaves your factory?

Yes, Both third part or clients test are workable.