Basic Info.

Product Description

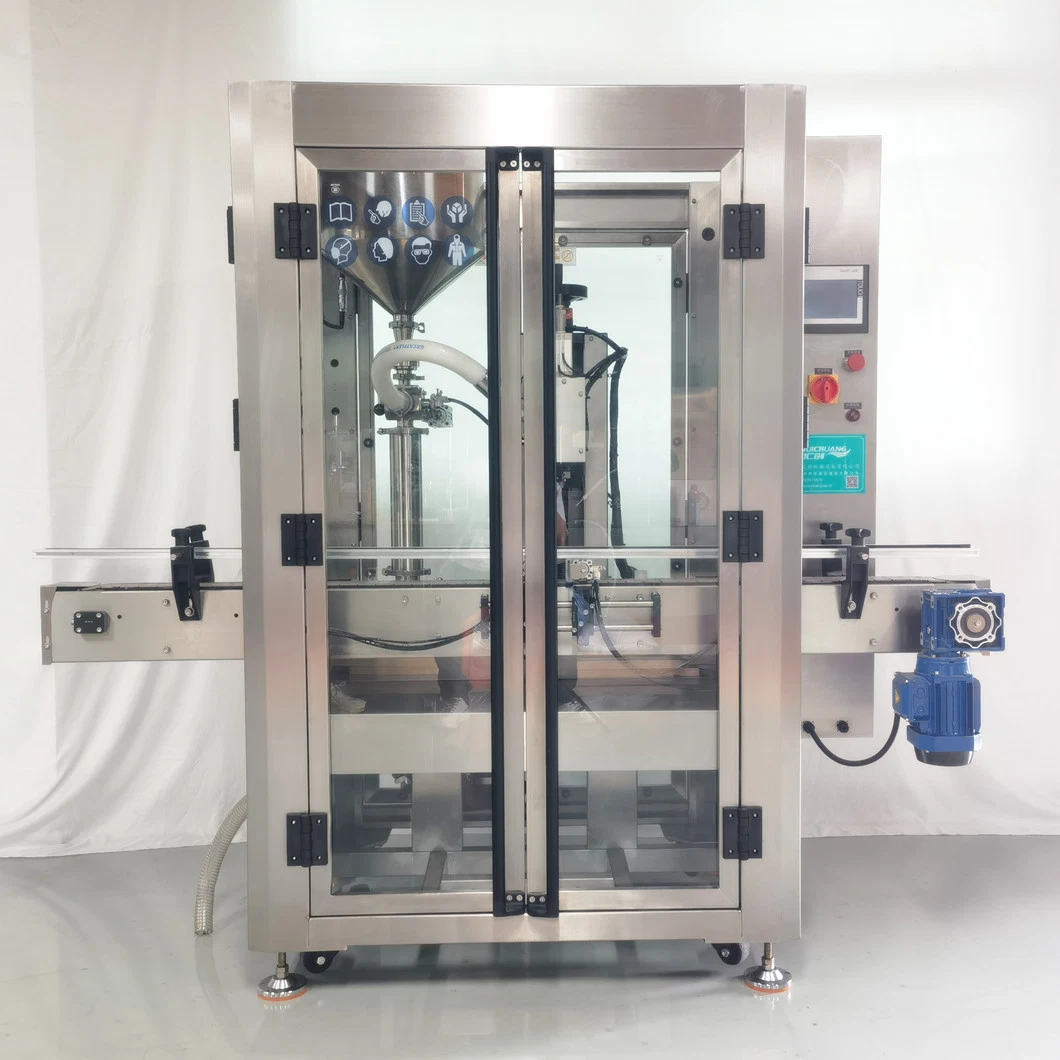

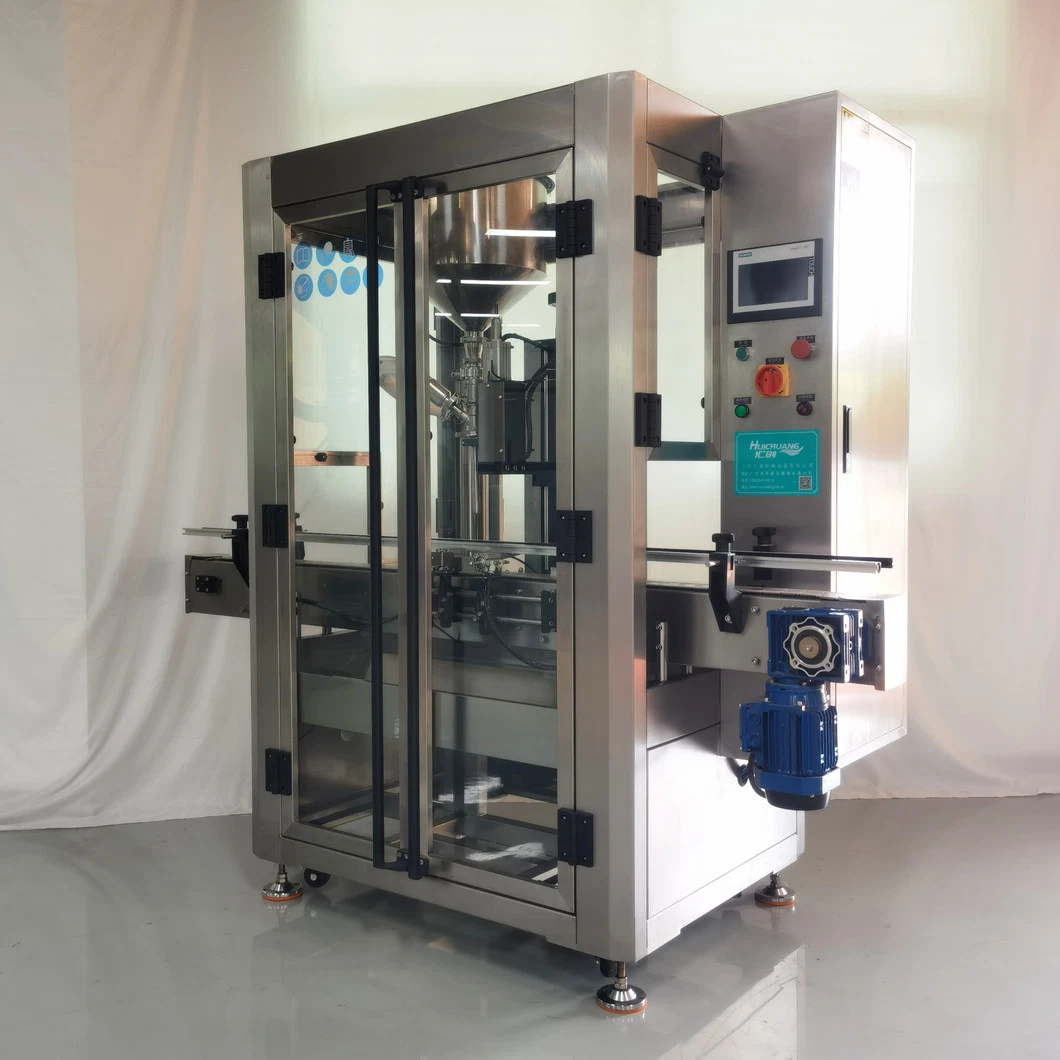

- The whole filling machine adopts stainless steel frame structure, transparent PC material protect frame, full meet GMP requirements.

- This filling machine automatically track bottle position for filling, the bottle does not need to stop,

- Touch panel operation more convenient and simple, filling nozzles adopts drip-tight design, ultrasonic liquid level control product transfer to hopper.

- Intelligent memory, automatic counting function, effective control filling quantity.

- Adopt motion control system and servo motor for tracking filling, tracking synchronous filling make fast filling speed, servo filling system with higher filling accuracy and precise positioning, filling precision is up to ±0.5%, the filling cylinders are independently controlled, and the capacity can be adjusted independently

- Filling capacity: 10-100ml; 20-250ml; 50-500ml; 100-1000ml etc.

- Filling type: Automatic tracking, synchronous filling (Follow up type and nozzles movable)

- Filling system: Servo motor + Piston pump

- Control system: PLC motion control system & Touch screen

- Filling speed: about 40-80 bottles/min (depend on filling volume and product viscosity)

- Filling accuracy: ±0.5%

- Material: Filling nozzles and contact part with product made by food grade stainless steel 304, feed tube made by food grade PVC

- Air Pressure: 0.4-0.8 MPa

| Machine name: | GZJ Full automatic Filling Machine |

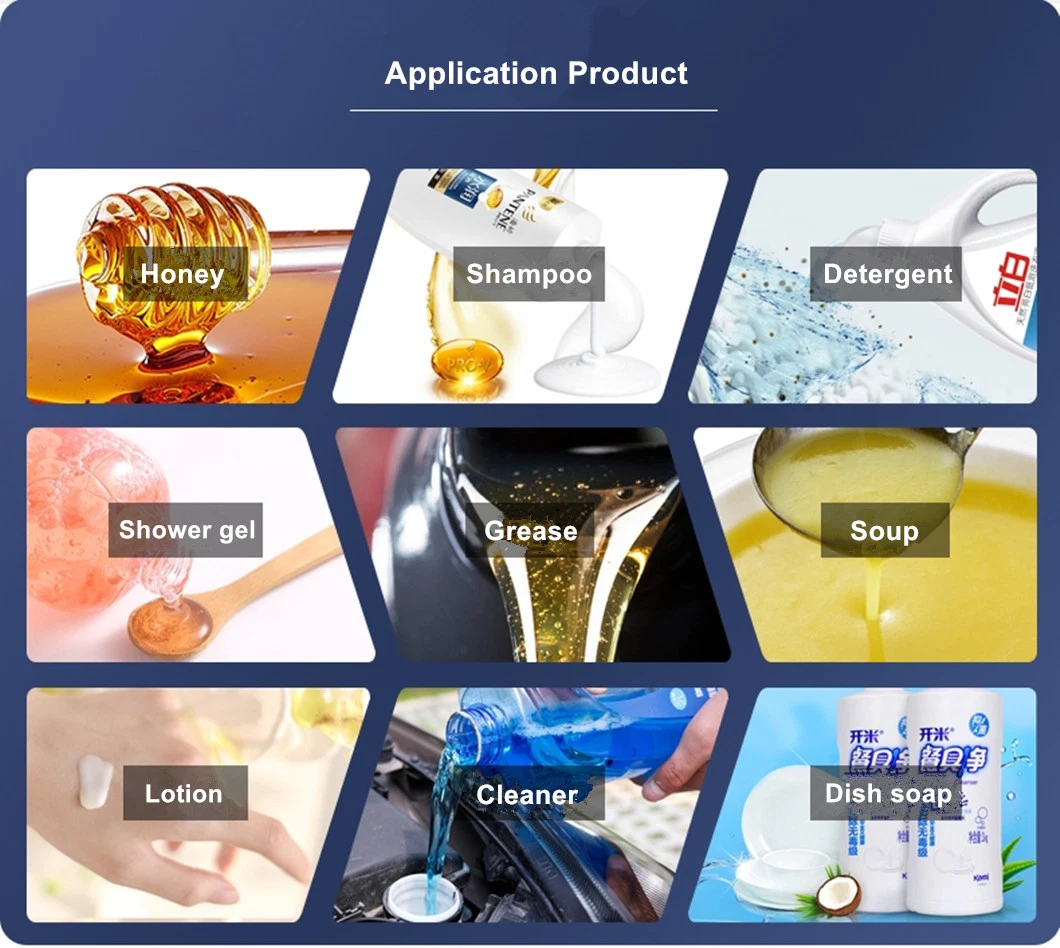

| Filling product: | Cream/ointment/lotion/paste/shampoo/soap/detergent/semi-liquid product |

| Filling volume: | 10-100ml; 25-250ml; 50-500ml, 100-1000ml,200-2500ml; 500-5000ml |

| Capacity: | 0-80Pcs/Min |

| Tube material: | Jar, bottle, can etc. |

| Filling nozzle: | Leakage-proof |

| Working accuracy: | ±1% |

| Air pressure: | 0.4-0.8Mpa |

| Air Consumption: | 0.05m³/min |

| Machine dimension: | 2500*1100*1900mm L*W*H |

| Net Weight: | 450kg |

1. Daily Chemical & Cosmetics Industry:

Such as baby cream, skin cream, face cream, shaving cream, shaving cream, lotion, shampoo, toothpaste, cold cream, sunscreen cream,face cleanser, moisture cream, liquid soap etc;

2. Food Industry:

Sauce, mayonnaise, juice, cheese, oral, nutrition, infant food, chocolate, sugar , tomato paste etc;

3. Pharmacy Industry:

Paste, ointment, Latex, emulsions, salves (ointments), oral syrup, liquid. etc;

4. Chemical Industry:

Latex, saponification products, paints, coatings, resins, adhesives, lubricants and the like.

Machine Image

GMP Project:

FAQ:

1. Q: How about the after sales service for automatic filling Machine?

A: We provide 2 years warranty for large equipment like full automatic filling Machine line. provide 1 year for small Cosmetic filling Machine, such as small batch Cosmetic filling Machine series. Machine guaranty and technical support lifetime for all kind of Machine. All machine's parts can be replaced for free within the warranty period if broken (excluding error operation).

2. Q: Is it difficult to install the automatic filling Machine?

A: The work shop should prepare full facility such as power and air compressor. For the first installation, engineer will be sent to set machine and do the machine training as long as manual instruction. For the further problems come out, we will provide solution video/photo instruction as well.

3. Q: What's the Cosmetic automatic filling Machine lead time?

A: For the standard machines, we can delivery within 35 days. If it is customized by customer(OEM), the lead time is 40-50 days.

4. Q: How can you control the quality?

A: We have a responsible QC department that strictly controls quality, all of our machines will be tested during production process, and will be tested again before packaging. wooden packaging is strong and safety for long delivery.

5. Please feel free to contact us with any question. We will provide you with one-stop service

Our Services:

1) Provide 24-hour service hotline for Cosmetic automatic filling Machine.

2) Reply and find out solution within the shortest time according to customer's requirement.

3) Provide on call service to help customer solve problems.

4) Provide free of machine installation as well as commissioning, and inform customer how to do the machine maintenance.

5) Prepare customer's feedback tracking within one week after machine installation until meet customer's satisfaction.

6) Provide one year guaranty and lifetime maintenance.

7) One-stop service for workshop decoration, selecting machines and installation service etc.